What's behind your trailer wheels

- Premier Boat and RV

- Nov 13, 2025

- 3 min read

Ever wonder what your vehicle is rolling on?

Here is a glimpse behind your wheels...

A Simple Guide to Trailer Axles, Hubs, Bearings & Brakes

Whether you tow a boat, RV, utility trailer, or travel trailer, there’s a lot happening behind your wheels that most owners never see. Yet these hidden components are some of the most important safety systems on your entire rig. Understanding how they work—and the warning signs when something’s wrong—can save you from breakdowns, costly repairs, or dangerous failures on the road.

In this guide, we break down the essential parts behind the wheels and explain what each one does.

1. Axles: The Backbone of Your Trailer

Your trailer’s axles support the full weight of your boat or RV and transfer that load to the wheels.

There are two main types:

Leaf-spring axles — the most common on boat and RV trailers; durable, simple, and serviceable.

Torsion axles — smoother ride, quieter operation, but can’t be easily rebuilt and must be replaced as a unit.

Key functions:

Carry the full trailer weight

Absorb shock from bumps in the road

Maintain proper wheel alignment

Common issues:

Bent axles (causing uneven tire wear)

Worn leaf springs

Broken U-bolts or hangers

Worn axle spindles ~ installing new bearings on worn and pitted spindles will result in premature bearing wear.

A damaged axle doesn’t just wear tires—it can cause sway, vibration, excessive heat and instability at highway speeds.

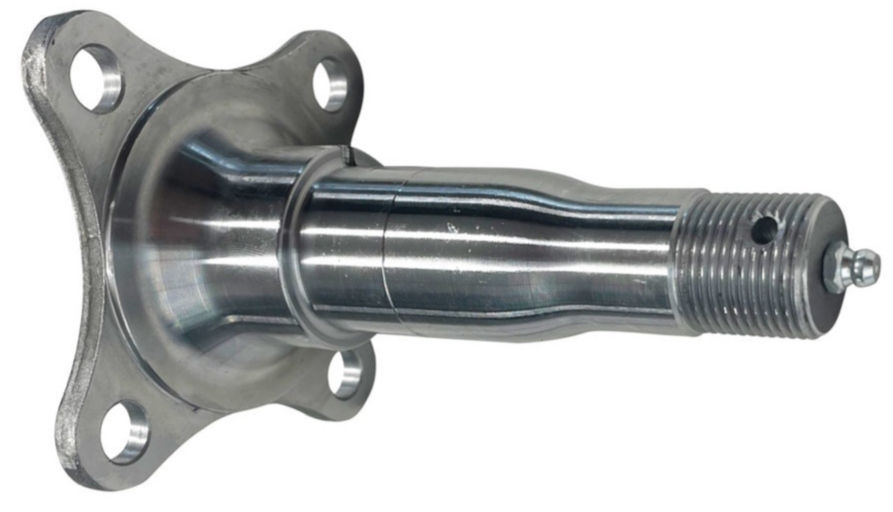

2. Hubs: Where the Wheel Meets the Axle

The hub is the connection point between your wheel and axle spindle. It houses the bearings and provides the mounting surface for your wheel.

Inside the hub you’ll find:

Inner bearing

Outer bearing

Grease seal

Grease cavity

Sometimes an integrated brake drum (for electric drum systems)

Boats often have galvanized hubs to resist corrosion from water. RVs typically run standard steel hubs designed for highway heat and load.

Signs of hub problems:

Grease leaking onto the wheels or inside the rim

Grinding or humming noises

A wheel that feels “wobbly” when shaken

Hub too hot to touch after driving

A hub failure can lead to a wheel coming off—one of the most dangerous trailer failures.

3. Bearings: Small Parts With Huge Responsibility

Bearings allow your wheels to spin smoothly with minimal friction. They’re small, inexpensive, and absolutely critical.

What they do:

Reduce friction between moving parts

Allow the hub and wheel to rotate freely

Handle the trailer’s weight and forces from acceleration/braking

Why maintenance matters:

Bearings rely on grease to stay cool and lubricated. When grease breaks down—or water enters the hub—bearings overheat quickly and can seize.

For boat trailers:

Launching at ramps means hubs get dunked in water. Even with bearing buddies, water intrusion is common.

This is why annual repacking (or more often for heavy-use trailers) is essential.

4. Brakes: Your Trailer’s Most Overlooked Safety System

While tow vehicle brakes do a lot of work, your trailer brakes are essential for safe stopping—especially with heavy boats or RVs.

Types of trailer brakes:

Electric drum brakes (common on RV trailers)

Electric over hydraulic disc brakes (premium stopping power)

Surge brakes (common on boat trailers; activated by trailer compression)

What brakes include:

Brake drums or rotors

Brake shoes or pads

Actuator (electric or hydraulic)

Wiring or hydraulic lines

Breakaway switch (legal requirement on RVs and many trailers)

Common problems:

Weak braking or pulling to one side

Squeaking or grinding

Rusted hardware (especially on boat trailers)

Overheated drums

Failed actuator or wiring issues

Poor or unbalanced brakes dramatically increase stopping distance and stress your vehicle’s braking system.

5. Why Regular Maintenance Is Critical

These components work hard, carry heavy loads, and face constant heat, moisture, and dust. Regular service helps you avoid:

Wheel bearing failures

Brake loss or brake lockup

Roadside breakdowns

Tire blowouts caused by heat from bad hubs

Costly mid-season repairs

Recommended maintenance schedule (general guideline):

Component | Service Interval |

Bearings (repack or replace) | Every 12 months or 10,000–12,000 km |

Brakes (inspection) | Every 12 months |

Axles & springs | Every 12–24 months |

Brake fluid (if hydraulic) | Every 2 years |

Boat trailers (high-use) | Every 6 months |

6. What Our Technicians Look For

When you bring your trailer to Premier Boat & RV, we check:

Bearing condition & lubrication

Brake shoe/pad thickness

Magnet operation (electric brakes)

Brake drum wear

Axle alignment

Hub temperature

Suspension wear (shackles, springs, bushings)

Tire wear that might indicate hidden issues

Our goal is simple: keep you safe, keep you rolling, and protect your investment.

Final Thoughts: What’s Behind Your Wheels Matters

While axles, hubs, bearings, and brakes sit quietly behind your wheels, they carry the full weight of your adventures. A small issue—like a dry bearing or worn brake shoe—can quickly turn into a dangerous and expensive failure.

A proper inspection gives you peace of mind every time you hit the road or launch your boat.

Comments